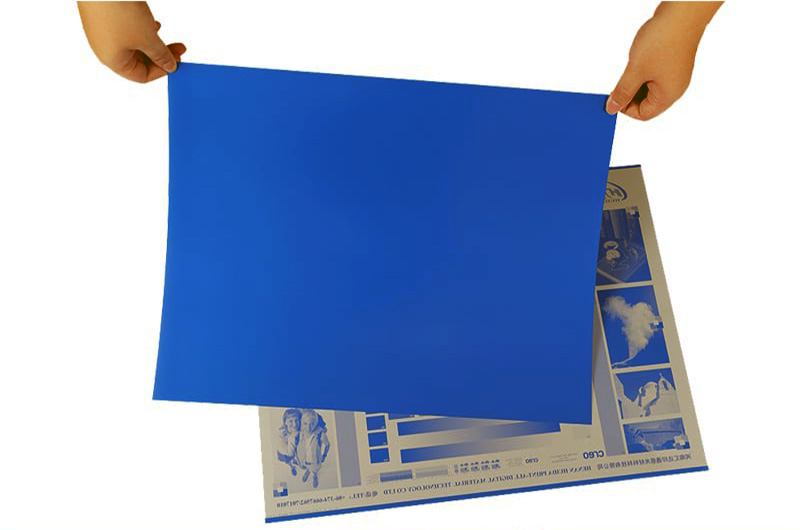

Ps Plate Offset Printing

PS Plate Offset Printing is a commonly used printing plate in offset printing technology, widely used in offset printing presses. The main material of the PS plate is aluminum, with a photosensitive coating on the surface, offering high precision and a long service life, making it suitable for high-quality printing production.

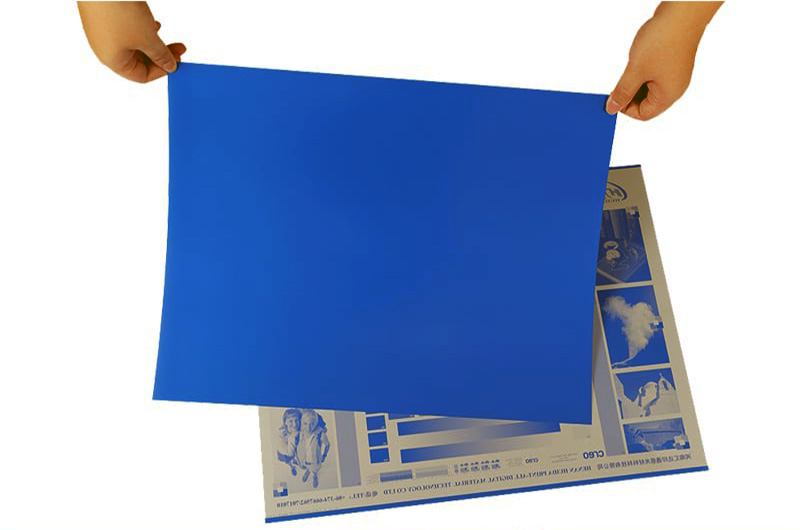

PS Plate Offset Printing Material and Structure

-

Aluminum Substrate: The base material of the PS plate is typically high-quality aluminum, which provides strong rigidity and good flatness. The aluminum substrate offers firm support, preventing deformation during printing and ensuring stable print quality.

-

Photosensitive Coating: The surface coating of the PS plate is a photosensitive material, typically composed of photoresin and other chemical components. This photosensitive coating undergoes a chemical change when exposed to light, forming the print image during the exposure process.

-

Rough Gas-Conducting Layer: The PS plate has a layer of fine particles or a rough gas-conducting layer that helps facilitate the flow of gases and prevents bubbles from forming during printing, thereby improving print quality.

PS Plate Offset Printing Characteristics

-

Multi-Layer Particle Structure with Smooth Coating: The PS plate uses a multi-layer particle structure, with a smooth coating that ensures precise reproduction of details during printing. The uniformity of the particles and the smoothness of the coating effectively reduce errors in the printing process.

-

Fast Photosensitive Speed: The photosensitive coating of the PS plate has a fast reaction speed, making the exposure process more efficient. The fast photosensitivity helps improve production efficiency and shortens the printing cycle.

-

Good Dot Reproduction: The PS plate can accurately reproduce fine dots, particularly in high-quality offset printing, ensuring clear presentation of fine dots and improving the delicacy of printed images.

-

Wide Exposure and Development Tolerance: The exposure and development process of the PS plate has a high tolerance, meaning that slight deviations during exposure and development still result in good print quality. This is crucial for offset printing, where precise operation is required.

-

Quick Water-Oil Balance: The PS plate quickly reaches a water-oil balance, making the control of ink volume and moisture more precise and reducing waste and adjustment time during the initial stages of printing.

-

Wear-Resistant Particles: The particles in the photosensitive coating of the PS plate are highly wear-resistant, capable of withstanding long-term use during printing, thus reducing quality degradation caused by wear.

-

Long Printing Life: Due to its sturdy aluminum substrate and wear-resistant coating, the PS plate has a relatively long service life. Even in high-density, high-intensity production environments, it maintains stability for a long time, reducing the need for frequent plate replacements.

-

Cost-Effective Printing: The PS plate is highly cost-effective, especially for large-scale printing. Its durability and fast photosensitive reaction help lower production costs.

-

International Standard Holes: PS plates typically feature perforations designed according to international standards, ensuring compatibility with different models of offset printing presses and smooth loading onto the press.

PS Plate Offset Printing Types

In PS plate (Photopolymer Plate) offset printing, two common types are single-layer PS plates and double-layer PS plates.

|

Characteristics

|

Single-Layer PS Plate

|

Double-Layer PS Plate

|

|

Application Range

|

Small to medium batch, general quality printing tasks

|

High-quality, high-precision printing tasks

|

|

Cost

|

Relatively low

|

Relatively high

|

|

Dot Reproduction Quality

|

Relatively simple

|

Finer, better reproduction of images and text

|

|

Printing Quality

|

Average

|

High quality, can handle complex patterns and text details

|

|

Service Life

|

Shorter

|

Longer, more wear-resistant

|

|

Suitable Applications

|

Daily commercial printing, packaging printing, etc.

|

Premium packaging, precision labels, advertising printing, high-quality publishing

|

|

Production Volume

|

Suitable for small to medium batch production

|

Suitable for large-scale production, especially high-demand printing tasks

|

Single-Layer PS Plate

Structure and Features:

-

Structure: The structure of the single-layer PS plate is relatively simple, typically consisting of a photosensitive coating on an aluminum substrate. The coating is primarily made of photosensitive resin, providing a certain degree of sensitivity and wear resistance.

-

Photosensitive Coating: The photosensitive coating is sensitive to ultraviolet light, and when exposed to UV light, the coating undergoes a chemical reaction, forming water-soluble or oil-soluble parts for the subsequent image transfer.

-

Cost: The production process of the single-layer PS plate is relatively simple and cost-effective, making it suitable for cost-sensitive, small to medium-sized printing tasks.

Application Range and Advantages:

-

Printing Requirements: Suitable for general quality printing needs, such as everyday commercial printing, packaging printing, etc.

-

Printing Quality: Due to its simple structure, the dot reproduction capability and precision of the single-layer PS plate are relatively lower, making it suitable for tasks where detailed reproduction is not critical.

-

Service Life: The durability and service life of the single-layer PS plate are relatively short, making it more appropriate for small to medium batch printing.

Double-Layer PS Plate

Structure and Features:

-

Structure: The double-layer PS plate has multiple photosensitive layers applied to the aluminum substrate, typically consisting of two layers: a base layer and a photosensitive layer. The base layer provides better adhesion and wear resistance, while the photosensitive layer offers higher sensitivity and finer dot reproduction.

-

Photosensitive Coating: The photosensitive coating of the double-layer PS plate is more refined, providing higher precision in image reproduction, making it ideal for high-quality printing needs.

-

Durability: With its double-layer structure, the double-layer PS plate demonstrates superior wear resistance and a longer service life, making it suitable for long-term, high-intensity printing tasks.

Application Range and Advantages:

-

Printing Requirements: Suitable for high-quality printing tasks, such as premium packaging, precision patterns, and printing with fine details. Common applications include fine label printing, commercial advertisements, high-quality packaging, and publishing.

-

Printing Quality: The double-layer PS plate can achieve finer dot reproduction, with higher image and text precision, capable of handling complex patterns and fine details.

-

Service Life: Due to its higher wear resistance, the service life of the double-layer PS plate is typically longer than that of the single-layer version, making it more suitable for large-scale production and long-term use.

PS Plate Offset Printing Applications

PS plates are widely used in various printing production processes, especially in offset printing.

-

Book and Magazine Printing: PS plates ensure high-quality printing results, especially suitable for printing large volumes of books and magazines, ensuring clarity and detail in both text and images.

-

Packaging Printing: PS plates are used for printing packaging materials such as paper boxes and bags, accurately reproducing design patterns and colors to enhance the appearance of the packaging.

-

Commercial Printing: This includes printing for posters, advertising flyers, and leaflets. The high precision and durability of the PS plate make it an ideal choice for commercial printing.

-

Fine Image and Text Printing: PS plates preserve the details of images and text well, suitable for high-precision printing tasks such as artwork reproduction and fine illustrations.

PS Plate Offset Printing Advantages

-

High Precision Printing: PS plates can reproduce very fine dots, making them ideal for printing tasks that require high precision in both images and text.

-

Strong Adaptability: Whether for single-color or multi-color printing, PS plates perform excellently and offer good compatibility with various printing systems.

-

Cost Efficiency: Although the initial investment for PS plates may be relatively high, their long service life and efficient production speed offer significant cost advantages for large-scale production.

As an essential material in offset printing, PS plates play a critical role in ensuring print quality, improving production efficiency, and reducing costs. Their excellent physical properties and high precision make them the preferred material in most offset printing fields, particularly for high-quality and large-scale production.

The following PS and CTP plate may interest you

Further reading: offset ctpctp plates for offset printingctp offset machinectp offset printingctp offset printing platesoffset printing ctp plateoffset printing plate making machine