Positive CTCP Plate(Double Layer)

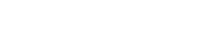

The Positive CTCP Plate (Double Layer) is a technology used in the printing industry that directly converts digital images into printing plates.

The Positive CTCP Plate (Double Layer) is a high-performance printing plate widely used in modern printing industries.

The Positive CTCP Plate excels in image rendering and processing speed, capable of handling large volumes of data, making it suitable for professional users who require high precision and efficiency.

Positive CTCP Plate (Double Layer) Features

1. Double-layer Coating Structure

- Durability Layer: The first layer of coating is designed to enhance the durability of the plate, providing good abrasion and chemical corrosion resistance.

- Photosensitive Layer: The second layer of coating is specifically designed for image transfer, effectively capturing and transmitting the printed pattern.

2. Enhanced Durability

Due to the double-layer design, the Positive CTCP Plate demonstrates higher compressive strength and stability under high-intensity printing conditions, allowing it to withstand more demanding printing environments, reducing image quality degradation from wear, and extending its lifespan.

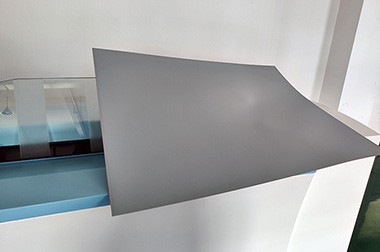

3. Exposure and Development

The exposure process is similar to that of single-layer plates, typically using ultraviolet light for exposure. However, due to the double-layer structure, the development process may require more precise adjustments to ensure even development of both layers of coating.

4. Cost Factors

The manufacturing process is relatively complex, involving more materials and techniques, resulting in a higher overall cost, making it suitable for users pursuing high quality.

Positive CTCP Plate (Double Layer) Advantages

1. Increased Durability

The double-layer structure gives the plate a longer lifespan, suitable for prolonged printing operations, reducing the need for frequent plate replacements.

2. Exceptional Performance

With its excellent resistance to chemical and mechanical wear, the plate ensures stable performance and consistent print quality in various printing environments.

3. Strong Adaptability

Suitable for various printing needs, especially large-scale commercial printing and packaging, it can meet the high quality and durability requirements of customers.

4. High-Quality Images

CTCP plate-making printing can produce clear and sharp high-quality images. The digital plate-making system can precisely control the etching process, ensuring consistent and high-quality images.

5. Fast Turnaround Time

CTCP plate-making printing offers a fast turnaround time, making it an ideal choice for businesses that require rapid printing services. The use of a digital plate-making system eliminates the need for film-based plate-making processes, significantly reducing the time required to produce the plates.

6. Cost-Effective

Compared to traditional offset printing methods, CTCP plate-making printing is a more cost-effective printing technology. The use of digital plate-making systems eliminates the film-based plate-making process, thus reducing overall printing costs.

7. Environmentally Friendly

CTCP plate-making printing is an environmentally friendly printing method, as its digital plate-making system does not use the harmful chemicals required in film-based plate-making processes, reducing negative impacts on the environment.

Positive CTCP Plate (Double Layer) Disadvantages

1. Higher Cost

Due to the complexity of the manufacturing process and increased material costs, the Positive CTCP Plate (Double Layer) has a relatively high usage cost, which may not be suitable for small printing companies with limited budgets.

2. Complex Handling

The double-layer structure may make the handling and transportation process somewhat complicated, requiring operators to possess a certain level of technical skill to ensure no issues arise during development and printing.

3. High Equipment Requirements

Due to its special coating and developing needs, specific equipment and technical support may be required, increasing the costs of equipment investment and maintenance.

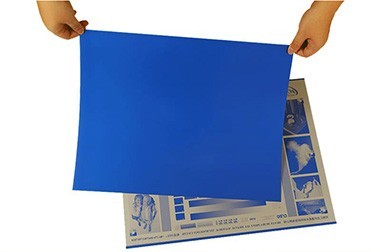

Positive CTCP Plate (Double Layer) Application Scenarios

The Positive CTCP Plate (Double Layer) is most suitable for long-term printing projects that require high durability and consistent quality, such as large-scale commercial printing, packaging, and labeling industries. These industries have strict requirements for print quality and production efficiency, and the advantages of double-layer coatings can effectively meet these needs. Compared to single-layer plates, double-layer plates show significant improvements in performance and durability, making them suitable for high-load production environments.

With its superior performance and durability, the Positive CTCP Plate (Double Layer) has become an ideal choice for the high-end printing market. However, its higher cost and complexity in handling also require companies to consider carefully when making a selection.

Positive CTCP Plate Technical Data Sheet

| Plate type | CTCP Plate |

| Usage: | Offset Printing, Digital Printing |

| Style | Positive |

| Gauge: | 0.15mm, 0.20mm, 0.25mm, 0.30mm, 0.40mm |

| Spectral sensitivity: | 410nm |

| Exposure energy: | 50 - 60 Mj/Cm2 |

| Developing temperature: | 23+/-2 degree |

| Resolution: | 2~98% at 200lpi |

| Developing time: | 30 - 40s |

| Run length: | 50 000 - 100 000 impressions . |

| Shelf time: | 18 months |

| Trademark: | Haomei or customized |

| Transportation Package: | Export standard, seaworthy package |

| Specification: | 0.15mm 100PCS/box;0.25mm 50PCS/box;0.30mm 50PCS/box; 0.40mm 30 PCX/box; customized. |

| Origin: | China |

| HS code: | 37013024 |

What is a CTCP Plate?

CTP technology can be divided into photopolymer CTP technology (including visible light, purple laser, and UV light) and thermal CTP technology. Additionally, CTcP (Computer-to-Contracted Plate) technology is a new plate-making method formed by modifying existing printing conditions. Compared to traditional CTP plates, CTcP plates offer more advantages.

CTcP (Computer-to-Traditional Plate) is a relatively new printing technology that has been widely used for high-quality image printing. CTcP printing combines the advantages of digital and traditional printing. The entire process involves creating an image on a computer and transferring it to a traditional printing plate, which is then used to print the image onto paper or other materials.

CTcP plate-making printing uses a digital plate-making system, which employs laser technology to etch the image onto the printing plate. This laser system is controlled by specialized software, enabling precise adjustments during the etching process to achieve high-quality image output. Compared to traditional offset printing plates, the plates produced by CTcP have higher resolution and better printing quality.

What is the Difference Between CTP and CTCP Plates?

Here is a comparison of the main differences between CTcP and CTP plates in the form of a table, which clearly shows the differences between the two.

| Item | CTCP | CTP |

| Exposure Material | Uses regular PS plates, digital information directly imaged | Uses specialized CTP plates with a photo-sensitive layer, digital information imaged |

| Material Cost | Lower cost, regular PS plates are widely used | Higher cost, coating process is complex and expensive |

| Exposure Technology | Uses short-arc UV high-pressure mercury lamps as the light source, with digital dot imaging technology and magnetic levitation drive | Relies on strict laser light sources with high wavelength precision |

| Printing Adaptability | Works well with printing processes | Requires precise integration with printing processes, lower adaptability |

| Equipment Lifespan | Exposure technology has little impact, lifespan is relatively long | Exposure technology has a significant impact, lifespan may be shorter |

The following PS and CTP plate may interest you

Further reading: ctcp platectcp plate making machinectcp printing platespositive thermal ctp plate