Flexo Ctp Machine

What is a Flexo CTP Machine?

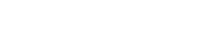

A Flexo CTP (Computer-to-Plate) machine is used in the flexographic printing industry to directly produce printing plates from digital files. The term "CTP" refers to the process of creating plates without the need for traditional film-based methods, thus streamlining workflows, improving efficiency, and enhancing the overall quality of printed materials.

Features of Flexo CTP Machine

- Direct Plate Imaging: Unlike traditional methods that require film negatives, a flexo CTP machine directly exposes the plate material to lasers, eliminating the need for film processing.

- Digital Workflow: The flexo CTP system is driven by digital data, typically from prepress files like PDF or TIFF. Compared to older analog methods, this digital workflow ensures higher precision and consistency.

- Plate Imaging Technology: The machine uses laser imaging technology to expose the flexo plate, which is typically made from photopolymer or rubber depending on the specific application.

- High-Resolution Imaging: Flexo CTP machines can achieve high resolution, which is critical for ensuring clear text, fine details, and consistent color reproduction on flexo prints.

Flexo CTP eliminates the need for film and chemicals in traditional plate-making processes, reducing waste and improving the sustainability of the printing process.

Advantages of Flexo CTP Machine

- Faster Turnaround Time: By bypassing the film development process, flexo CTP can produce plates more quickly and reduce press setup time.

- Cost-Effective: Eliminating the need for film and reducing manual intervention makes CTP systems more cost-effective in the long run.

- Consistency and Quality: The precision of digital imaging ensures that each plate is identical, resulting in consistent print quality.

- Reduced Errors: The digital nature of the system reduces human errors and ensures that the final print output matches the original design accurately.

Typical types of flexo CTP machines:

- Flatbed Flexo CTP: This type of CTP system exposes the plate in a flat position and is typically used for high-quality flexo printing applications.

- Inline Flexo CTP: Inline systems integrate plate exposure with other processes, providing higher efficiency in continuous workflows.

Flexo CTP machines are widely used in the packaging industry, especially for printing on materials like corrugated cardboard, labels, flexible packaging, and other materials that require flexographic printing.

Haomei Aluminum is a well-known supplier of flexo CTP machines. With our extensive experience in providing high-quality flexo CTP systems, thermal CTP systems, and violet CTP systems, we have earned a strong reputation in the market.

List of Haomei Aluminum Flexo CTP Machine

| Model NO | Max Produce Capacity |

| Haomei-6048F-1 | 1.4 ㎡/h |

| Haomei-6048F-2 | 2.8 ㎡/h |

| Haomei-6048F-3 | 4.2 ㎡/h |

Flexo Ctp Machine Technical Parameters

| Model | Haomei-6048 |

| Productivity | 4.2㎡/h, |

| Max. plate size | 1524×1270mm(60×50 inches) |

| Plate thickness | 0.15~6.35mm |

| Output media | Digital flexographic water-washable letterpress plates; Digital flexographic water-washable plates; Digital flexographic solvent-washable plates; Thermal(0.15mm) CTP plates; Dry film |

| Application | Label printing, Trade mark |

| Resolution | 4800dpi |

| Loading method | Manual loading |

| Interface | Gigabit Ethernet |

| External dimension | L×W×H=2650mm×1600mm×1300mm |

| Power supply | 220V AC 50/60Hz 4kW Peak (Single phase) |

| Environment | Temperature 18-30℃ |

What are the different types of flexo machines?

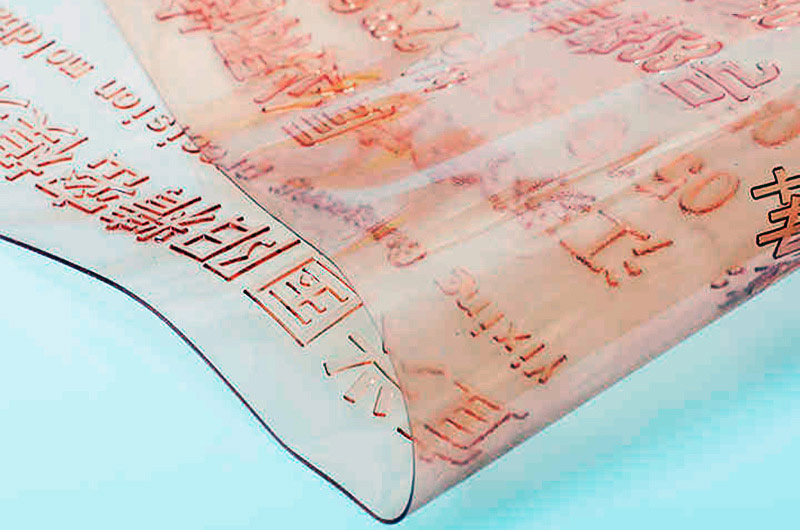

- Flexo Photopolymer Plate Making Machine: This machine is used to create photopolymer flexographic plates, which are essential for the flexographic printing process. It uses light-sensitive photopolymer materials that are exposed to UV light to form printing plates. The machine includes systems for exposing, developing, and curing the plate, enabling high-quality, durable plates suitable for printing on various substrates.

- Flexo Resin Plate Making Machine: Similar to photopolymer plate makers, this machine specifically produces flexo plates made from resin-based materials. The resin plate-making process involves using UV light to harden the resin material on the plate, creating a durable, high-resolution plate for the flexographic printing process. These plates offer advantages such as excellent ink transfer and long-lasting print quality.

- Photopolymer CTP Flexo Plate Machine: A Computer-to-Plate (CTP) photopolymer machine for flexo printing, this system directly transfers digital files to photopolymer plates without the need for traditional film. This CTP process ensures precise, high-quality plate production, allowing for faster plate making and reduced material waste. The system typically includes exposure units and development sections.

- Flexo CTP Machines: This refers to a range of machines used in the flexographic printing industry that employ the Computer-to-Plate (CTP) method. These machines directly image flexo plates from digital files, improving accuracy and efficiency. CTP technology in flexo plate making allows for faster setup times, precise plate production, and high-quality print results.

- Photopolymer CTP Plate Machine: A machine designed for creating photopolymer plates using CTP technology. It exposes digital images directly onto photopolymer material, allowing for precise and consistent plate production. This machine is widely used in the flexographic printing industry for high-quality and cost-effective plate production, offering improved turnaround times compared to traditional methods.

- Midsize Flexo CTP Machine: This is a flexo plate-making device designed for various packaging applications, including labels, flexible packaging, folding cartons, and corrugated cardboard packaging. It supports both flexo and letterpress printing, with sizes ranging from 200 x 100 mm to 1200 x 1067 mm, a resolution of 4800 dpi, and a throughput of 4 to 6 square meters per hour. The machine accommodates multiple screening methods, providing up to 200 lpi line count, ensuring accurate color reproduction, clear details, and smooth gradients.

- Large-format Flexo CTP Machine: This is a direct flexo plate-making device for large-size packaging. It can directly image resin plates without the need for film and intermediate processing, reducing operational costs and improving efficiency. It supports sizes from 200 x 100 mm to 1524 x 1067 mm, an output resolution of 4800 dpi, and a production rate of 4 to 6 square meters per hour. The machine supports various screening methods, with a maximum line count of 200 lpi, delivering high-quality print results and catering to large-format flexo printing needs.

Popular Flexo CTP Machines

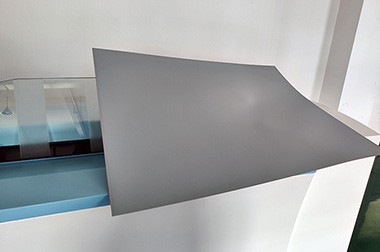

- 1.14mm Digital Photopolymer Flexographic Printing Plate: A thin, high-quality digital photopolymer plate used in flexographic printing. The 1.14mm thickness ensures precise printing for high-definition images, ideal for small to medium print runs.

- 3.94mm Thickness Flexible Digital Flexographic Plate: A thicker, flexible digital plate used in flexographic printing for larger or more intricate prints. This thickness provides durability and supports various printing substrates.

- 2.84mm Digital Flexographic Photopolymer Printing Polymer Plate: A digital photopolymer plate with a 2.84mm thickness, designed for high-quality, flexible printing applications. It is known for its precise image reproduction and resilience.

- 1.7mm Digital Flexographic Polymer Plate: A thinner digital polymer plate, typically used for fine-line printing in flexographic applications. It offers high detail, sharpness, and excellent ink transfer.

- 6.35mm Resin Photopolymer Flexo Printing Plate: A resin-based photopolymer plate with a 6.35mm thickness, ideal for heavy-duty flexo printing tasks. Known for its robustness and ability to handle thicker ink applications.

- 5.50mm Hot Sale Flexographic Flexo Printing Plate: A popular, mid-thickness flexographic printing plate that offers versatility and is often used in high-demand, commercial flexo printing jobs.

- 2.84mm Analogue Flexo Printing Plate: An analogue version of the 2.84mm flexographic plate, typically exposed to UV light via a traditional method rather than digital imaging. Suitable for high-quality and high-speed printing.

- 1.70mm Flexo Plate for Flexo Printing: A specific flexo plate designed for high-resolution printing at a thickness of 1.70mm, suitable for precise and intricate designs in flexographic printing.

- 1.14mm Analog Flexo Photopolymer Plate: A thinner, analogue flexo plate exposed to UV light, used for high-definition and fine detail prints. Its 1.14mm thickness ensures accuracy in reproduction.

- UVA-LED Flexo Plate Exposure Machine for Flexo Plate Making: A specialized machine that uses UVA-LED light to expose photopolymer plates, offering high energy efficiency and precise exposure for digital flexo plates.

- Middle Size Flexographic Photopolymer Plate Making Machine: A mid-sized machine designed for the production of flexographic plates, suitable for medium-scale printing operations, offering efficient and accurate plate making.

- CDI Flexo CTP Digital Flexo Plate Making Machine: A Computer-to-Plate (CTP) system that directly transfers digital files onto photopolymer plates, improving workflow and eliminating the need for film.

- Automatic Photopolymer Flexo CTP Plate Making Machine: An automated CTP machine that streamlines the creation of flexographic plates, offering a faster and more efficient process for high-quality photopolymer plates.

- Digital Flexographic Water-Washable Letterpress Plates: Digital plates designed for flexographic and letterpress printing, using water-based technology for clean, eco-friendly plate processing.

- Photopolymer Flexo Digital Printing Plate: A high-performance, photopolymer-based plate for digital flexographic printing, known for its ability to produce sharp images and high-quality prints with precision.

- Corrugated Carton Flexo Printing Plate: Specifically designed for printing on corrugated cardboard, this flexo plate is robust enough to handle rough surfaces, ensuring high-quality printing on packaging materials.

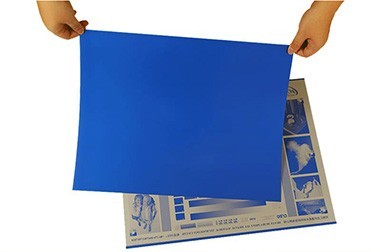

The following PS and CTP plate may interest you

Further reading: flexo ctp machinectp flexo plate making machinectp flexo