Feb. 28, 2025

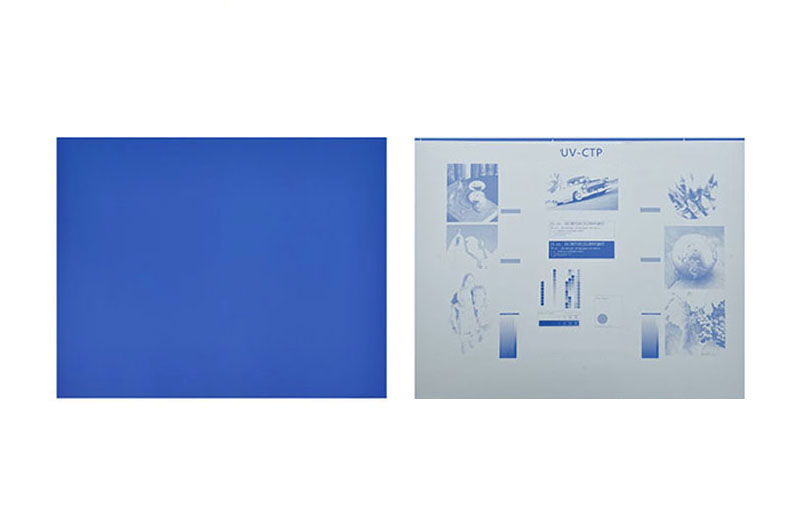

UV CTP Plate is a printing plate used for digital printing, specifically in Computer-to-Plate (CTP) technology. Unlike traditional plate-making processes, which transfer images onto plates using film (CTCP - Computer to Camera), UV-CTP plates directly create images using a digital process.

UV CTP plates are typically used as a replacement for traditional etching methods, as they offer lower production costs and reduced time requirements. They also provide better ink adhesion than other types of plates, helping to prevent smudges and improving image quality.

1. Single Layer UV CTP Offset Printing Plate

2. Double Layer UV-CTP Plate

3. UV-CTP Positive Plates

Single Layer UV CTP Offset Plates are suitable for economical mid-to-long run printing, meeting basic printing needs but requiring post-baking to improve print stability.

Double Layer UV-CTP Plates outperform single-layer plates in chemical resistance, resolution, and production efficiency, requiring no post-baking and are more suitable for high-efficiency long-run printing.

UV-CTP Positive Plates are a versatile category of plates, suitable for various types of inks and printing needs, offering high durability and print quality.

| Features | Single Layer UV CTP Offset Printing Plate | Double Layer UV-CTP Offset Printing Plate | UV-CTP Positive Plate |

| Spectral Sensitivity | 400-420 nm | 400-420 nm | 400-420 nm |

| Sensitivity | High Sensitivity | 40 mJ/cm² | High Sensitivity |

| Resolution | Reproducible stochastic screen up to 20 µm | Reproducible stochastic screen up to 20 µm | Reproducible high-resolution images, suitable for high-precision printing |

| Post-baking Requirement | Requires post-baking | No post-baking required | Depends on the specific product, usually does not require post-baking |

| Chemical Resistance | Moderate | High chemical resistance | High chemical resistance |

| Application Fields | Mid-to-long run printing, suitable for sheet-fed and commercial web offset printing | Long run printing, suitable for various inks, including UV inks, metallic inks, etc. | Widely used in commercial printing, packaging printing, newspapers, magazines, and other types of printing work |

| Suitable Ink Types | Suitable for conventional inks and UV inks | Suitable for UV inks, metallic inks, conventional inks | Suitable for conventional inks, UV inks, and metallic inks |

| Development Method | Uses specific developer liquid, with smaller development tolerance | Compatible with mainstream developer liquids, with larger development tolerance | Generally compatible with mainstream developer liquids, with good development tolerance |

| Production Efficiency | Moderate | High, as post-baking is not required | Moderate or high, depending on the specific model and production requirements |

| Durability | Low, suitable for short to mid-term production | High, suitable for long-term press runs | High, suitable for high-quality, high-precision printing needs |

| Typical Applications | Mid-to-long run printing, packaging, commercial printing | Long run printing, packaging, and high-quality printing | High-end commercial printing, packaging, magazine, and newspaper printing, etc. |

Single Layer UV CTP Offset Printing Plate

The single-layer UV CTP offset printing plate is specifically designed for CTCP-UV (Computer to Conventional Plate-UV) imaging. This plate is a positive-working plate that uses UV-sensitive coating to capture the image directly from the digital files.

Spectral Sensitivity:

This plate has a spectral sensitivity in the range of 400-420 nm, which corresponds to the typical wavelength used by UV lasers in the CTP (Computer-to-Plate) imaging process.

Key Characteristics:

High Sensitivity and Resolution: The plate offers high sensitivity and resolution, enabling the reproduction of random screens up to 20 µm. This ensures fine detail and high-quality prints, even with complex images and fine halftone dots.

Post-Baking Capability: This plate can undergo post-baking, which improves the print durability and stability. After baking, it can still be used for long-run printing applications, including both sheet-fed and commercial web offset printing.

Applications:

Ideal for medium to long-run printing, especially for sheet-fed presses and commercial roll-fed presses. It is suitable for a wide range of printing applications, including packaging and general commercial printing.

Benefits:

Cost-Effective: This single-layer plate is often more economical due to its simplified design and reduced manufacturing complexity.

Good for Various Substrates: It is compatible with different types of paper, including coated and uncoated stocks.

Double Layer UV-CTP Plate

The double-layer UV-CTP positive plate is a more advanced version of the UV-CTP plate, offering additional features and benefits in terms of chemical resistance and print durability. It is also a positive-working plate but with a dual-layer construction for enhanced performance.

Spectral Sensitivity:

The spectral sensitivity remains in the range of 400-420 nm, similar to other UV-CTP plates, making it compatible with most UV-based CTP imaging systems.

Key Characteristics:

High Sensitivity (40 mJ/cm²): This plate features a higher sensitivity than single-layer plates, allowing for faster imaging and shorter exposure times. This results in quicker plate production and more efficient printing workflows.

High Resolution: Like the single-layer plate, it can reproduce random screens up to 20 µm, ensuring high-quality print results, even for detailed and fine images.

No Post-Baking Required: Unlike the single-layer plate, the double-layer UV-CTP plate does not require post-baking, which simplifies the production process and reduces time and costs.

Chemically Resistant: The double-layer construction offers excellent chemical resistance, making it more durable and longer-lasting, even when used with aggressive inks, including UV inks, metallic inks, and conventional inks.

Applications:

It is suitable for long-run printing, including large commercial printing jobs and packaging. It can be used with a variety of ink types and is ideal for printers that demand high performance and reliability in their printing process.

Benefits:

No Need for Post-Baking: The absence of the post-baking process enhances workflow efficiency, making it more convenient for high-volume printing environments.

High Durability: The chemical resistance and durability make it suitable for longer press runs without degradation in print quality.

UV-CTP Positive Plates

UV-CTP positive plates are a general category of plates that are positive-working and designed for UV-CTP imaging. These plates are sensitive to UV light and can produce high-resolution prints.

Spectral Sensitivity:

These plates typically have a spectral sensitivity in the range of 400-420 nm, making them suitable for use with standard UV-CTP imaging systems.

Key Characteristics:

Positive Working: UV-CTP positive plates are positive-working, meaning the imaged areas are removed during the development process, leaving the non-imaged areas intact.

High Resolution and Detail: These plates are capable of producing high-resolution images with very fine details, making them suitable for printing applications that require sharp text and images.

Flexibility: UV-CTP positive plates are used across a variety of printing jobs, from commercial and packaging printing to newspapers and magazines. They offer flexibility in handling different types of inks (UV, conventional, metallic, etc.).

Durability: These plates typically offer good durability, but their longevity depends on the specific construction (e.g., single-layer or double-layer).

Applications:

Commonly used for general commercial printing, packaging, and high-quality printing jobs that require precise color reproduction and sharp detail.

Benefits:

Versatility: Suitable for a wide range of printing applications and ink types.

High-Quality Output: Capable of producing high-quality prints with sharp details, making them ideal for high-end commercial and packaging printing.

Compared to traditional plate-making methods, UV-CTP plates offer higher image quality, faster production speeds, and lower costs. They can be printed on a variety of substrates and have environmental benefits, making them the preferred choice for many modern printing businesses, from commercial publishing to packaging.

Users viewing this material also viewed the following

Further reading: uv ctpuv ctp plate