Thermal Plate VS Processless Plate

Feb. 28, 2025

In printing technology, especially in the production of offset printing plates, thermal plates and processless plates are two types of plates used to transfer ink onto paper or other substrates. Both have specific advantages and applications, but they differ significantly in terms of production and usage.

- Thermal Plates are the preferred choice for high-end, large-volume commercial printing due to their excellent print quality, durability, and precision.

- Processless Plates are an ideal choice for printers looking to reduce environmental impact and simplify prepress processes by eliminating the need for chemical development.

They offer a more environmentally friendly alternative, but may not always match the durability and precision of thermal plates, making them better suited for shorter print runs or less complex applications.

Each plate has its own advantages, and the choice between them usually depends on factors such as environmental goals, print quality requirements, and production volume.

Key Differences Between Thermal and Processless Plates

| Feature | Thermal Plates | Processless Plates |

| Development Process | Requires chemical or water development. | No chemical development; water rinse or no rinse needed. |

| Environmental Impact | Higher chemical waste and environmental footprint. | Low environmental impact due to reduced chemical use. |

| Plate Durability | Highly durable, suitable for long runs. | Less durable than thermal plates but sufficient for shorter runs. |

| Imaging Process | Laser exposure using thermal technology. | Laser or UV exposure with specialized coatings. |

| Cost | Higher due to the need for development systems. | Potentially lower due to reduced pre-press costs. |

| Quality | High-quality image reproduction. | Good quality, but may not match thermal plates in terms of fine detail. |

| Press Suitability | High-end commercial printing, long runs. | Suitable for short to medium press runs, commercial printing. |

| Environmental Benefits | Limited (requires chemical developers). | High (no chemicals used in development). |

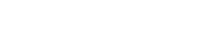

Thermal Plates

Thermal plates are a specialized type of photopolymer plate utilized in offset printing. They are designed to respond to heat, with their processing involving thermal exposure where a laser is employed to create an image for printing.

Key Features:

- Exposure Process: Utilizing a laser, thermal plates expose the surface, hardening the image areas and making them resistant to ink. Non-image areas are subsequently removed during development.

- Heat Activation: The laser's thermal energy activates the photopolymer coating, enhancing its resistance to solvents and ink, ensuring that only the exposed areas remain intact.

- High Image Quality: These plates deliver exceptional resolution and printing quality, making them ideal for high-end commercial applications.

- Durability: Known for their resilience and reliability, thermal plates can endure extended press runs and exhibit strong wear resistance.

- Pre-Press Processing: After exposure, thermal plates typically undergo a development process that may involve a chemical or water bath, depending on the specific type.

Advantages:

- Superior image resolution.

- Consistent print quality.

- Exceptional durability and longevity in press life.

- Capability to produce intricate details and small typefaces.

Applications:

Thermal plates are primarily used in high-end commercial printing, including magazines, brochures, packaging, and other materials where quality and consistency are paramount. They are particularly suited for long press runs.

Users viewing this material also viewed the following

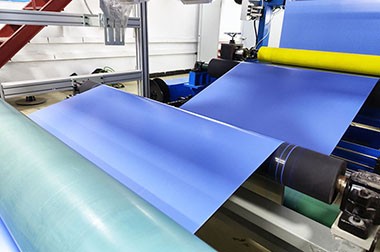

Processless Plates

Processless plates represent a modern advancement in printing technology, eliminating the need for traditional chemical development after exposure. These plates are also widely used in offset printing but are engineered to reduce or negate chemical processing requirements.

Key Features:

- No Chemical Development: The standout feature of processless plates is their lack of a traditional chemical development stage. After exposure, these plates are simply rinsed with water to remove unexposed areas.

- Water-Based Processing: Instead of harsh chemicals or solvents, processless plates typically utilize water or very mild solutions for cleaning, making them a more eco-friendly option.

- Exposure Process: Like thermal plates, processless plates employ laser or UV exposure to form the image. However, they feature a unique coating that reacts to exposure without necessitating a separate development step.

- Reduced Environmental Impact: By eliminating the need for chemical developers, processless plates significantly cut down on waste generated during the pre-press process.

- Cost-Effective: Over time, processless plates can prove to be more economical due to the absence of costs associated with chemical development and disposal.

- Environmental Advantages: With reduced chemical and water use, processless plates are viewed as a more sustainable choice compared to thermal plates.

Advantages:

- Lower environmental impact due to minimal chemical usage.

- Quicker processing times since no development stage is required.

- Cost savings from avoiding chemicals and development equipment.

- Streamlined pre-press process with fewer steps.

Applications:

Processless plates are ideal for commercial and short-run printing, where speed and environmental considerations are vital. They are often favored by smaller printing operations seeking to minimize chemical use and are well-suited for sustainable printing initiatives aimed at reducing waste and environmental impact.

Further reading: ctp thermalctp thermal platepositive thermal ctp platethermal ctpthermal ctp machinethermal ctp platethermal ctp systems