CTP Printing: Streamlining Workflows and Reducing Costs in Printing

Feb. 28, 2025

What is CTP Printing?

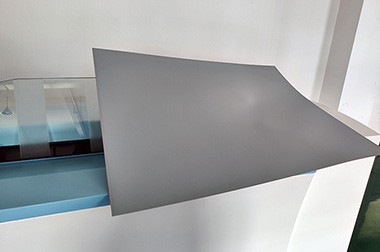

CTP (Computer-to-Plate) printing is a modern printing technology that directly transfers image information from a computer to a printing plate, eliminating the traditional step of transferring images to film first.

- Digital File Processing: Create digital image files using design software.

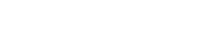

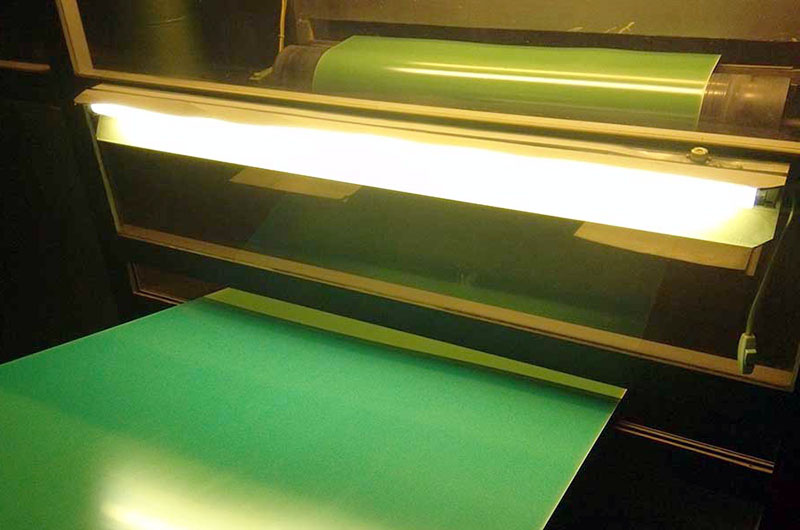

- Output to Printing Plate: Through CTP equipment, digital files are directly converted into printing plates, usually aluminum plates. This process involves using lasers to directly engrave the image onto the printing plate.

- Printing: Once the printing plate is ready, it can be used for printing on the press.

Advantages of CTP Printing

1. Eliminates the Film Production Step

Traditional printing requires converting digital files into film and then transferring the image from the film to the printing plate. CTP printing omits this process, directly transferring the digital image to the printing plate, avoiding the cumbersome steps and potential quality issues of film production.

2. Improved Clarity and Detail

Since CTP technology directly converts the image into the printing plate, it eliminates the blurriness and distortion that can occur during the film process, ensuring that the clarity and detail of the image are more precise. This is particularly important for high-quality printing, such as art printing and packaging.

3. Reduced Quality Loss

In the traditional film processing, issues like scratches and exposure variations can arise, affecting the final print quality. CTP printing significantly reduces the risk of these defects through digital processing, ensuring consistency and quality in output.

4. Higher Accuracy and Consistency

The alignment accuracy of CTP printing can typically reach ±1%, while traditional plate makers have an accuracy of ±2%. CTP maintains the precise position of the medium in the plate-making machine during the imaging process, avoiding deviations caused by improper film alignment in traditional methods.

5. Increased Production Efficiency

CTP printing can significantly enhance the output of printing plates. For example, CTP plate makers designed for newspaper production can output up to 300 12-inch (approximately 300 mm) plates per hour, while CTP systems used in commercial applications can output 60 B1 plates per hour. This high efficiency allows printing companies to respond more quickly to market demands.

6. Higher Resolution

CTP printing typically supports higher resolutions, such as 1270 DPI (dots per inch) for newspaper production and 2400 DPI for commercial printing. This enables printed products to achieve higher line counts and finer image quality, meeting high-end printing demands.

7. Cost Reduction

By eliminating the need for film, developing chemicals, and other materials, CTP printing can reduce material costs in the long run. Additionally, the high efficiency of CTP helps lower labor and time costs.

8. Reduced Environmental Impact

The implementation of CTP printing reduces the need for developing chemicals, thereby lowering its environmental impact and aligning with modern environmental standards.

9. Flexibility and Adjustability

CTP systems allow for quick adjustments to designs and layouts, better accommodating customers' personalized needs and market changes. This flexibility is especially important in short-run printing and fast-paced commercial environments.

Limitations of CTP Printing

Digital Dependency: CTP printing requires that all printed materials and layouts be based on digital files. This means traditional film or paper materials cannot be directly used for CTP production, limiting the use of certain non-digital designs.

If a CTP plate is damaged for any reason, or if errors occur while tearing the plate, or if corrections are needed after exposure, a completely new plate must be produced.

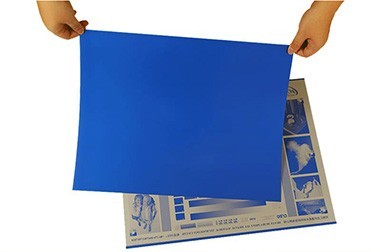

Haomei Aluminum specializes in thermal CTP plates, which come in two types: single-layer thermal CTP plates and double-layer thermal CTP plates.

Users viewing this material also viewed the following

Further reading: ctp plates for offset printingctp printingcomputer to plate printingctcp printing platesctp machine for printingctp offset printingctp offset printing platesctp printing plateoffset printing ctp plateoffset printing plate making machineplatesetter printing