Mar. 06, 2025

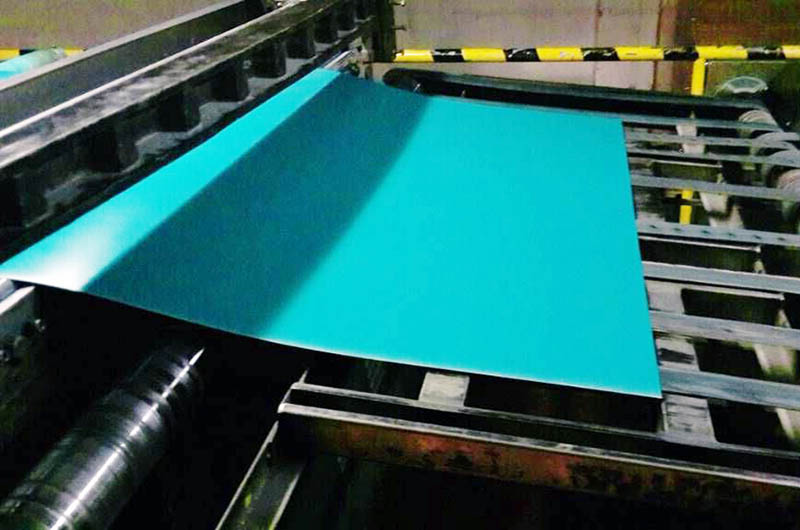

CTP (Computer-to-Plate) plates are a type of aluminum plate used in offset printing, coated with a photosensitive emulsion that is sensitive to laser beams. This emulsion reacts to the laser, allowing for the formation of a clear image based on the laser exposure. In the production process, the CTP plate is first exposed to laser light, where the energy of the laser selectively exposes the areas of the coating that will be printed. Subsequently, through a developing process, the unexposed coating is removed, leaving the desired image on the plate surface.

| Production Steps | Description |

| Coating with Photosensitive Emulsion | Evenly apply the photosensitive material on the surface of the aluminum plate to form the image in subsequent processes. |

| Laser Exposure | Use a laser to irradiate the plate, selectively removing the coating in the areas that will be printed. |

| Developing Process | Remove the unexposed coating, ultimately forming a clear image on the plate surface. |

Compared to traditional film-based plates, CTP plates offer several advantages. Firstly, they eliminate the need for film negatives, reducing the time and cost of the printing process. Secondly, CTP plates provide superior image quality and consistency, as digital files can be fine-tuned for accuracy and color correction. Thirdly, these plates are more durable, allowing for extended print runs without the need for re-platting.

| Advantages | Specific Description |

| No Film Negatives Required | |

| Time Savings | Significantly reduces the preparation time for printing, improving production efficiency. |

| Cost Reduction | Eliminates the costs associated with film production, thereby lowering overall printing costs. |

| Superior Image Quality | |

| Digital File Fine-Tuning | Allows for detailed adjustments to digital files, ensuring accuracy in color correction and image details. |

| Print Consistency | Ensures stable quality in every print run, reducing potential quality fluctuations common in traditional printing. |

| Greater Durability | |

| Increased Production Efficiency | Generally does not require re-platting, thus reducing machine downtime and enhancing production efficiency. |

| Strong Adaptability | Capable of meeting high-volume printing demands and adapting to various scales of printing tasks. |

HC Aluminum specializes in thermal CTP plates, which come in two types: single-layer thermal CTP plates and double-layer thermal CTP plates, each with the following characteristics:

Characteristics of Single-Layer Thermal CTP Plates

| Feature | Description |

| Operating Environment | Can operate under white light without preheating. |

| Quality Stability | Stable quality with good compatibility. |

| Dot Reproduction | Excellent dot reproduction, capable of accurately reproducing details. |

| Resolution | Dense oxidation layer, high-resolution printing. |

| Hydrophilicity | Outstanding hydrophilicity, maintaining optimal ink-water balance. |

| Photosensitive Coating | Unique photosensitive coating with high sensitivity and fast speed. |

Characteristics of Double-Layer Thermal CTP Plates

| Feature | Description |

| Operating Environment | Suitable for various printing environments. |

| Quality Stability | Strong stability, reducing quality fluctuations. |

| Dot Reproduction | Excellent dot reproduction, ensuring accurate reproduction of complex images. |

| Resolution | Double-layer design, maintaining high-resolution printing effects. |

| Hydrophilicity | Strong adaptability with good ink-water balance performance. |

| UV Resistance | UV-resistant ink extends the lifespan. |

| Developing Tolerance | Large developing tolerance with high operational flexibility. |

| Print Suitability | High print suitability, compatible with various types of printing presses. |

| Factor | Description |

| Print Volume | The print volume will determine the durability of the plates. For high-volume printing, more durable plates are needed to withstand longer print runs. |

| Plate Type | Choose the type of plate based on printing needs. Thermal plates are suitable for quick plate-making, while violet plates may be a more cost-effective option. |

| Image Quality | The required image quality will influence the choice of plate. High-quality, fine images typically require thermal plates. |

| Substrate | The type of substrate determines the type of CTP plate needed. For example, printing on non-porous substrates like plastic or metal requires thermal plates. |

| Plate Size | The required plate size must match the dimensions of the printing machine and the size of the print job. |

| Budget | Budget is a key factor in selecting the right CTP plates, as plate costs depend on type, size, and print volume. |

| Environmental Impact | The environmental impact of the plates is also an important consideration. Violet plates are generally more eco-friendly than thermal plates, as their manufacturing process has lower energy consumption and emissions. |

Users viewing this material also viewed the following

Further reading: ctp plates for offset printingctp printingcomputer to plate printingctcp printing platesctp machine for printingctp offset printingctp offset printing platesctp printing plateoffset printing ctp plateoffset printing plate making machineplatesetter printing