Apr. 03, 2025

A CTP (Computer-to-Plate) Plate Making Machine is a device used for direct plate-making in modern printing. CTP technology transfers digital images or text information directly onto printing plates, replacing traditional film-based processes. This enhances plate-making speed, precision, and quality.

CTP technology replaces the traditional Computer-to-Film (CTF) process by using digital files (such as PDF or TIFF) processed through a RIP (Raster Image Processor) and then directly imaging onto a photosensitive printing plate. This direct imaging ensures higher resolution, better registration, and consistent plate quality, which is crucial for offset printing, flexographic printing, and other printing applications.

Imaging Technology

Mechanical Structure Types

HC Aluminum manufacturers provide customizable features, robust quality control, and a global support network to ensure smooth operation and rapid troubleshooting.

The materials and compatibility of CTP plates vary:

| System | Components/Functions |

| Light Source System | The laser light source is the core of the CTP machine, commonly using violet lasers, red lasers, or infrared lasers. |

| The light source determines the resolution and compatibility with different plate materials. | |

| Plate-Making Platform | Used to secure the CTP plate materials (e.g., PS plates, thermal plates, or UV plates). |

| High-precision mechanical structures ensure stability and consistency during the plate-making process. | |

| Imaging Unit | Uses lasers to write digital images or text directly onto the photosensitive coating of the plate. |

| Supports various resolutions (e.g., 2400dpi, 1200dpi) to meet different printing requirements. | |

| Control System | Integrated computer systems handle digital image processing, plate-making parameter settings, and device operation control. |

| Typically supports mainstream file formats like PDF and TIFF. | |

| Feeding and Output System | Automated feeding and output functions for high-volume production needs. |

| Cooling and Cleaning Devices | Prevent overheating and ensure efficient operation of the imaging unit. |

| Cleaning devices remove impurities from the plate, improving plate quality. |

The following table details the key processes and functions of a CTP plate-making machine, helping you understand how the entire plate-making process works.

| Process | Detailed Description |

| Image Data Input | Users process digital files (e.g., PDF, TIFF) into a format readable by the plate-making machine using RIP (Raster Image Processor) software. |

| RIP software handles image color separation, color management, and resolution adjustments to ensure output data meets the machine's requirements. | |

| Laser Exposure | Lasers selectively expose the plate surface based on processed image data. |

| The laser beam moves across the plate's photosensitive coating, creating physical or chemical changes in exposed areas that differ from unexposed ones. | |

| The precision and resolution of exposure directly impact printing quality. | |

| Developing (if applicable) | The exposed plate undergoes a developing process, typically using developer solutions to remove unexposed photosensitive coatings, fixing the image on the plate. |

| Some new CTP plates use developer-free technology, eliminating the developing step, reducing chemical use, and improving efficiency. | |

| Rinsing and Drying | Rinsing removes the unexposed coating from the plate surface, ensuring only the exposed image remains. |

| After rinsing, the plate is dried to remove moisture and developer, making it ready for printing. | |

| The dried plate can immediately be used for printing production. |

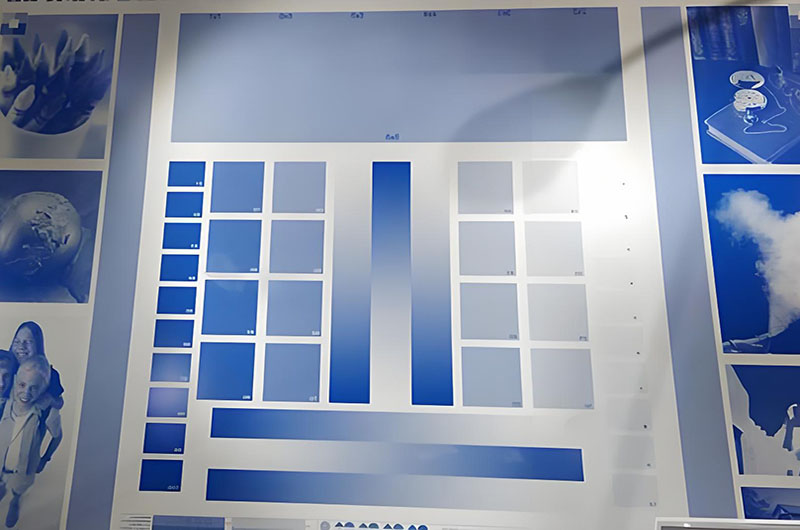

According to the plate-making materials, CTP Plate Making Machines can be divided into Thermal CTP Plate Making Machines, Ultraviolet Laser CTP Plate Making Machines, and UV CTP Plate Making Machines.

| Features | Thermal CTP Plate Making Machine | Ultraviolet Laser CTP Plate Making Machine | UV CTP Plate Making Machine |

| Image |

|

|

|

| Resolution | High | Medium-High | Medium |

| Plate Making Speed | Medium | Fast | Relatively Slow |

| Operating Cost | High | Low | Relatively Low |

| Initial Investment | High | Medium | Relatively Low |

| Applicable Scenarios | High-end Printing, Long-term Printing | Newspapers and Small to Medium-sized Printing | Packaging, Short-run Printing |

| Item | Description |

| Description | Thermal CTP Plate Making Machines use thermal sensitive plates and perform plate making through thermal energy reactions, featuring high precision and high stability, suitable for commercial and packaging printing fields. |

| Working Principle | The laser head emits infrared laser beams, which irradiate the heat-sensitive coating of the thermal sensitive plate. The heat-sensitive coating undergoes physical or chemical changes, and after development, washing, and drying steps, a printing plate ready for direct printing is obtained. |

| Features | High Resolution: Typically supports 2400dpi or higher, suitable for fine images and text printing. |

| High Stability: Strong resistance to environmental interference, suitable for long-term storage and use. | |

| Good Imaging Consistency: Uniform plate quality, suitable for large-scale printing demands. | |

| Applicable Scenarios | Commercial Printing: Magazines, books, advertising materials, and other high-requirement printed products. |

| Packaging Printing: High-quality packaging materials such as cigarette boxes and cosmetics packaging. | |

| Advantages | Strong durability; thermal sensitive plates support a longer printing lifespan. |

| Suitable for long-term continuous operation, reducing equipment maintenance frequency. | |

| Disadvantages | Higher cost of thermal sensitive plates and equipment, large initial investment. |

| Higher dependence on the development step. |

| Item | Description |

| Description | The Violet Laser CTP Plate Making Machine uses a short-wavelength violet laser light source, compatible with violet laser plates, featuring low energy consumption, high speed, and cost efficiency. |

| Working Principle | The laser head emits violet laser light with a wavelength of approximately 405nm, forming an image on the photosensitive coating of the violet laser plate. After exposure, the plate undergoes development to produce the final printing plate. |

| Features | Fast plate-making speed: The violet laser light source responds quickly, suitable for high-speed printing needs. |

| Low energy consumption: The device has lower power consumption. | |

| Economical: The cost of violet laser plates is lower than that of thermal plates. | |

| Application Scenarios | Newspaper printing: Environments requiring efficient plate production. |

| Small to medium-sized printing enterprises: Customers seeking cost-effectiveness and efficiency. | |

| Advantages | Lower initial investment cost, suitable for users with limited budgets. |

| Low operating cost, with economical violet laser plates. | |

| Long light source lifespan, reducing replacement costs. | |

| Drawbacks | Slightly inferior resolution and image refinement compared to thermal CTP. |

| Lower plate stability, requiring specific storage and environmental conditions. |

| Item | Description |

| Description | The UV CTP Plate Making Machine uses traditional PS plates (positive or negative) as plate-making materials, combined with ultraviolet laser imaging technology, featuring strong compatibility and low operating costs. |

| Working Principle | The laser head emits ultraviolet light (usually with a wavelength below 355nm), activating the photosensitive coating on the plate surface. After exposure, the PS plate undergoes development and washing, forming image areas. |

| Features | Strong compatibility: Supports traditional PS plates, allowing users to retain their existing printing processes. |

| Cost-effective: PS plates are cheaper than thermal and violet laser plates. | |

| Environmentally friendly: Optional development-free UV plates reduce chemical waste discharge. | |

| Application Scenarios | Packaging printing: Low-cost packaging plate production, such as food packaging and labels. |

| Advertising printing: Posters, flyers, and other medium-short run printing. | |

| Advantages | Low investment threshold: Uses traditional PS plates without requiring additional equipment modification. |

| Easy operation: Requires minimal technical skills from operators. | |

| Good cost control: Economical PS plates and consumables. | |

| Drawbacks | Lower image quality and resolution compared to thermal and violet laser devices. |

| Not suitable for ultra-long runs due to lower plate durability. |

| CTP Plate Making Machine Advantages | Description |

| High Precision and Consistency | CTP machines directly image the plate, reducing errors from multiple processing steps and improving image clarity. |

| Efficiency | CTP machines eliminate the film process, significantly shortening plate-making time and reducing printing turnaround by 50%. |

| Cost Savings | CTP machines reduce labor and material costs while minimizing chemical usage (in process-free systems), enhancing overall cost efficiency. |

| Environmental Benefits | CTP machines minimize toxic chemical usage (such as developers) and support process-free plates. Fewer chemicals and less waste make CTP systems more eco-friendly. |

| Automation | CTP machines feature automatic plate loading, remote diagnostics, and user-friendly interfaces, simplifying workflow. |

CTP plate-making machines represent a major advancement in prepress technology. By directly converting digital files into printing plates, these machines improve speed, quality, and cost efficiency while reducing environmental impact. Whether using thermal, violet, or UV systems, the choice depends on specific printing needs—balancing resolution, production volume, and operating conditions for optimal results.

| Category | Application Scope | Features | Specific Scenarios | Advantages |

| Commercial Printing | Books, magazines, newspapers, and other large-scale production products | High-efficiency plate-making, high resolution, long lifespan | Textbooks, novels, photo books, advertising magazines, daily newspapers | Enhances production efficiency, reduces waiting time between plate-making and printing, minimizes error rates |

| Packaging Printing | Packaging boxes, plastic bags, labels, and other large-format plates | High flexibility, cost-effectiveness, precision | Food packaging, cosmetic packaging, industrial labels | Meets the demands for large-format and complex designs, quickly adapts to diverse needs |

| Book Printing | Educational books, literary works, picture books, and other types | Clear text, image-text combination, durable plates | Textbooks, art books, children’s picture books | Speeds up plate-making, meets publishers' time requirements, high-quality printing |

| Newspaper Printing | Daily newspapers, weekly publications, and other newspaper plate-making | Quick response, large-scale production, cost control | Daily news, weekly content | Improves timeliness, ensures clarity and consistency of printed content |

| Specialty Printing | Business cards, tickets, posters, labels, cards, and diverse needs | Diversity, high resolution, flexibility | Premium business cards, tickets, advertising posters | Satisfies personalized, short-run demands, enhances the scope of business services |

| Security Printing | Tickets, banknotes, and other high-security products | Anti-counterfeiting technology, high precision, material compatibility | Tickets, entry passes, banknotes | Enhances product security and anti-counterfeiting performance, meets special requirements |

1. Choose Based on Production Volume

High-speed machines are suitable for large-scale production

Applicable Scenarios:

High-speed CTP plate-making machines are designed for high-volume production in printing plants, suitable for frequent daily plate-making tasks and large print runs, such as in newspaper offices, magazine publishers, and large packaging plants.

Features:

Recommendations:

If your printing volume is large and plate-making demands are frequent, prioritize high-speed machines to ensure short production cycles and timely delivery.

Medium- and low-speed machines meet the needs of small and medium enterprises

Applicable Scenarios:

Targeted at small and medium-sized printing companies or users with moderate efficiency requirements, such as customized printing services, small packaging companies, and personalized printing studios.

Features:

Recommendations:

If your company is starting or has limited order volume, medium- and low-speed machines are more cost-effective choices.

2. Choose Based on Plate Requirements

Thermal plates are ideal for high-quality printing

Applicable Scenarios:

Suitable for fields requiring high-quality images and text, such as books, photo albums, and advertising prints.

Features:

Recommendations:

If you focus on high-end printing markets (e.g., high-resolution printing and large-scale tasks), thermal CTP equipment is the best choice.

UV plates are suitable for cost-sensitive scenarios

Applicable Scenarios:

Used in packaging printing, newspaper printing, and other areas sensitive to costs but with moderate printing quality requirements.

Features:

Recommendations:

If cost-effectiveness is your priority or you need more flexible plate choices, consider UV CTP equipment.

3. Brand and Service

Choose a reputable brand to ensure after-sales service and technical support

Importance:

Plate-making machines are high-precision equipment. Selecting a well-known brand guarantees product quality and comprehensive after-sales services.

Recommendations:

When investing in CTP equipment, prioritize brand reputation and after-sales support to reduce operational technical risks.

4. Scalability

Consider whether it supports upgrade functions to meet future business needs

Importance:

The printing market changes rapidly. A device’s scalability determines its long-term value.

Features:

Recommendations:

If your company plans to expand its business or upgrade its product line, choose CTP equipment that supports future scalability to avoid high costs of replacing devices later.

Users viewing this material also viewed the following

Further reading: ctp machinectp plate making machinecomputer to plate machineflexo ctp machinectp flexo plate making machinectcp plate making machinectp computer to plate machinectp machine for printingctp offset machinectp plate machineoffset printing plate making machinesmall ctp machinethermal ctp machineviolet ctp machine