Mar. 20, 2025

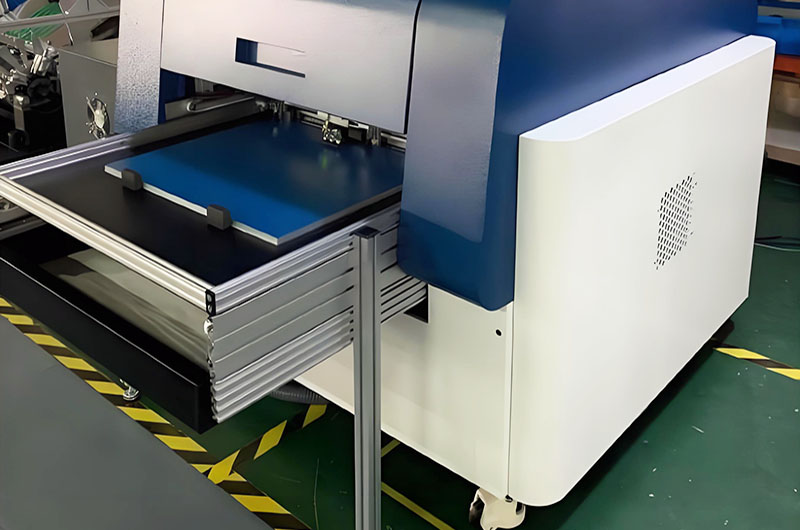

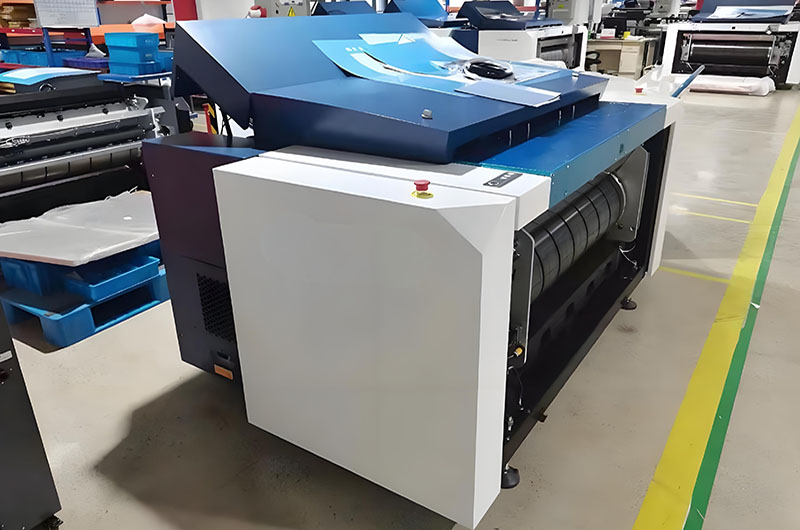

A Computer-to-Plate (CTP) machine is a digital imaging device used in the printing industry to directly transfer digital designs to printing plates, without the need for a film intermediary. This technology enhances the efficiency, accuracy, and cost-effectiveness of prepress workflows and is primarily used in offset printing.

A Computer-to-Plate (CTP) machine is a key device in modern printing that eliminates the need for traditional film methods, thereby improving efficiency and printing quality.

CTP machines use laser technology to etch digital images onto printing plates. The process includes:

| CTP Type | Image | Description |

| Thermal CTP |

|

Thermal CTP utilizes infrared lasers to expose thermal plates, providing high resolution and durability. It offers exceptional precision, making it ideal for commercial printing applications like magazines and brochures. |

| Violet CTP |

|

Violet CTP uses violet laser diodes for exposure, offering an economical and efficient solution for a wide range of printing needs. It provides faster imaging speeds and is suitable for medium-volume jobs, such as smaller commercial or packaging runs. |

| UV CTP |

|

UV CTP employs ultraviolet light sources to expose plates, enabling faster imaging and broad compatibility with various plate types. It is ideal for flexographic printing and specialty plates, commonly used in packaging and other high-speed production processes. |

| Component | Description |

| Imaging Engine | Utilizes lasers (thermal, violet, or UV) to expose the plate. |

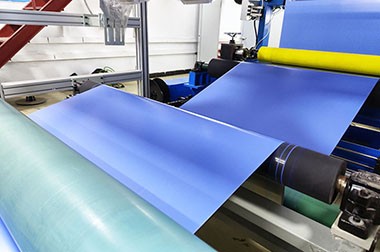

| Plate Types | Thermal Plates: Exposed by infrared lasers; require heat development. |

| Photopolymer/Violet Plates: Use violet laser diodes; suitable for high resolution. | |

| Processless Plates: Eliminate chemical development, reducing environmental impact. | |

| Raster Image Processor (RIP) | Converts digital files into high-resolution raster images, handling color separation and screening. |

| Drum or Flatbed System | Internal Drum: Plate fixed inside a drum; single laser head moves axially. |

| External Drum: Plate wrapped around a rotating drum; multiple lasers write simultaneously. | |

| Flatbed: Plate lies flat; lasers or LEDs move across it. | |

| Plate Handler | Automated systems that load/unload plates, boosting productivity. |

| Processor | Develops exposed plates (if required), using chemicals or heat. |

By integrating CTP technology, printing operations can achieve higher efficiency, lower costs, and better print quality, making it the industry standard.

| Application | Description |

| Commercial Printing | CTP Machine for Printing plays a pivotal role in commercial printing applications such as magazines and brochures. It ensures high-quality, sharp, and consistent prints, enabling detailed designs and vibrant color reproduction while reducing production costs and enhancing workflow efficiency. |

| Packaging | CTP Machine for Printing is widely used in packaging for applications like corrugated packaging and labels. It enables high-quality, vibrant designs on various materials, ensuring precision and color control while improving production speed and reducing waste. |

| Newspapers | CTP Machine for Printing is essential in the newspaper industry, where high-speed printing and lower-resolution plates are required. It allows for fast production of newspaper pages, reducing time and labor costs while maintaining clear text and images for efficient news cycle demands. |

CTP machines have revolutionized the prepress process by simplifying plate production, providing scalability, and supporting various printing needs. Their adoption aligns with the industry's shift towards sustainability and digital integration.

| Core Evaluation Indicators | Description |

| Resolution and Imaging Accuracy | Resolution (such as 2400 dpi or above) directly affects the sharpness of the dot edges. |

| High-resolution equipment can achieve finer gradient levels and frequency modulation dots (FM Screening). | |

| Test the device's ability to reproduce minimum dots (such as 1%-99% dot stability), to avoid the loss of highlight/shadow details. | |

| Laser light source technology (such as violet laser, thermal, etc.) affects imaging stability. Thermal technology typically makes the dot edges clearer. | |

| Plate Compatibility and Developer Matching | Confirm whether the CTP supports the types of plates (such as photopolymer plates, thermal plates) that are compatible with the printing process. |

| The compatibility of the developer machine's chemical solutions must be tested simultaneously to avoid dot expansion or uneven development. | |

| Supplier | HC Aluminum is a professional supplier of Ctp Machines, offering sample testing, checking screen uniformity, gradient transitions, and text sharpness. |

| Core Points | Description |

| Quality Evaluation | Prioritize verifying the stability of thermal technology and compare the imaging accuracy of different brands. |

| Capacity Matching | Select the CTP model based on the speed of the printing equipment to avoid waste of resources by blindly pursuing high speed. |

| Upgrade Potential | Prefer models that support speed upgrades (such as Kodak Victory 800 series) to meet future capacity expansion needs. |

| Operating Costs | Consider the costs of plates, maintenance, and energy consumption. Prioritize models that are easy to maintain and have lower operating costs. |

When selecting a CTP (Computer-to-Plate) plate making machine in the printing industry, it is necessary to consider various factors such as equipment performance, capacity requirements, dot quality, and operating costs.

Users viewing this material also viewed the following

Further reading: ctp machinectp plate making machinecomputer to plate machinectp computer to plate machinectp machine for printingctp plate machineoffset printing plate making machinesmall ctp machinethermal ctp machineviolet ctp machinectp offset machine