Apr. 03, 2025

The Computer-to-Plate (CTP) system directly receives digital files from a computer and precisely and quickly outputs the image to the printing plates required. By eliminating the traditional film step, CTP not only improves efficiency but also significantly reduces costs and environmental impact.

Computer to Plate Machine is a device that directly outputs the graphic information edited by a computer onto a printing plate through a digital process. It is a core prepress technology in the printing industry.

The Computer to Plate Machine eliminates the traditional need for intermediate films, thereby improving efficiency, accuracy, and overall print quality, fundamentally transforming the prepress workflow.

| Features | Description |

| Direct Imaging | The core advantage of CTP equipment lies in its "direct imaging" capability, which allows image files created in desktop publishing (DTP) applications to be directly output to the printing plate, simplifying the traditional computer-to-film (CTF) process. |

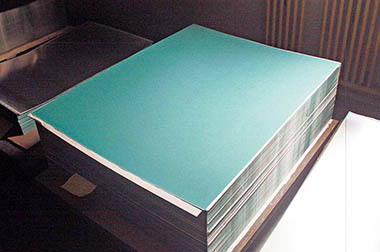

| Variety of Plate Materials | CTP equipment supports various plate materials, including aluminum plates and polyester plates. Aluminum plates are suitable for high-quality, large-volume printing, while polyester plates are ideal for lower-cost, small-volume printing, ensuring print quality and durability. |

| Efficiency and Cost Savings | CTP accelerates the entire printing process with direct plate-making, reducing production costs. Compared to traditional plate-making processes, CTP can directly output plates, saving on film, chemicals, and labor costs, while improving plate quality and reducing the likelihood of rework and repairs. |

| High-Quality Output | CTP equipment features high-precision digital imaging capabilities, ensuring that the image details on the plate are clear and accurately reproduced, meeting the high-quality printing standards, especially for prints with complex colors and high image precision requirements. |

Computer-to-Plate (CTP) has brought significant improvements to the printing industry by simplifying the process, enhancing efficiency, and reducing environmental pollution.

CTP technology offers improved image quality, production efficiency, registration accuracy, and cost-effectiveness, providing better plate-making options for the printing industry. It has significant advantages in various printing applications.

| Features | Description |

| Reduced Generation Process, Simplified Printing Process | CTP technology eliminates the step of transferring film images to plates, directly imaging onto the plate, removing the use of films and developing chemicals in traditional plate-making processes. This reduces chemical dependency and enhances production efficiency. |

| Improved Image Clarity and Detail Representation | CTP avoids quality loss during film handling, such as scratches and exposure variations. Digital imaging technology directly projects high-resolution images onto the plate, achieving clearer and more detailed representations. |

| Faster Plate Production Speed and Higher Consistency | CTP systems accelerate plate production speed, shorten production cycles, and improve consistency during the printing process, ensuring minimal differences between batches of plates, thereby maintaining stable high-quality output. |

| Reduced Costs | CTP eliminates the use and processing steps of film, lowering plate production costs. In high-output production environments, significant cost savings are achieved, while also reducing chemical consumption, meeting modern environmental demands. |

| Improved Registration Accuracy and Image Reproducibility | CTP systems ensure precise image alignment, avoiding the registration errors associated with traditional plate-making. This enhances the accuracy of image placement and edge repeatability for each print, ensuring stable print quality, suitable for high-precision print products. |

| Reduced Defects, Enhanced Plate Quality | During the CTP imaging process, the plate material is kept in precise position, preventing dust, scratches, and other defects from affecting plate quality. Compared to traditional plate-making processes, where film handling can introduce flaws, the direct plate-making approach of CTP minimizes quality issues and ensures perfect image output. |

| Significant Increase in Plate Output | CTP systems, in large-volume production environments such as newspapers and commercial printing, output much faster than traditional methods. For instance, up to 300 12-inch plates can be produced per hour, making it ideal for high-quality and high-volume applications. |

| Wide Application Flexibility | CTP systems adapt to different printing needs, from single-color and two-color outputs for small printing presses to high-resolution commercial plate-making outputs. Standard laser printers can be used for low-quality, low-volume scenarios, while high-end dedicated plate makers can be used for high-demand applications, meeting varying quality and volume needs. |

Working Principle

Through the laser imaging system, digital files are processed and imaged directly onto a specially coated photosensitive plate using photothermal or photochemical technology. The imaged plate is then developed and can be used for printing, with the entire process requiring no manual intervention.

System Components

| Key Components | Description |

| Digital File Processing | High-resolution digital files are created using desktop publishing (DTP) software and converted into raster images via Raster Image Processing (RIP) software, handling color separation and screening. |

| Plate Exposure | The prepared digital image is transferred directly to a photosensitive printing plate. |

| Laser Imaging | CTP machines use laser technology (thermal, violet, or ultraviolet) to expose the plate, depending on the plate chemistry and required quality. |

| Imaging Systems | Three main construction types: |

| Internal Drum – The plate is mounted inside a rotating drum while a moving laser head projects the image. | |

| External Drum – The plate is wrapped around the outside of a drum, with one or more laser heads exposing it as the drum rotates. | |

| Flatbed – The plate lies flat, and the laser moves across its surface line-by-line. | |

| Plate Development | After exposure, the plate may require processing (chemical development) or be "processless," meaning it’s ready for printing with minimal post-exposure treatment. |

| Automation & Handling | Modern CTP systems often include automated plate loading/unloading and integrated digital workflow software to streamline the process. |

| Classification Dimension | Main Types and Characteristics |

| Imaging Technology | Thermal Type: Uses thermal plates, suitable for high-quality commercial printing. |

| Photopolymer Type: Suitable for high-speed newspaper printing. | |

| Mechanical Structure | External Drum: Mainstream universal type, providing high imaging stability and accuracy. |

| Internal Drum / Flatbed: Suitable for special format requirements. | |

| Plate Compatibility | Dedicated CTP Plates: Must match the light source characteristics of the equipment. |

| Standard PS Plates: Only for CTcP devices, lower cost but weaker stability. |

Uses infrared laser exposure on specially designed thermal printing plates. Thermal systems offer very high resolution and are less sensitive to ambient light.

Uses violet laser diodes for exposure, which may be more cost-effective and provide faster imaging speeds, but they may require special safe-light conditions.

Uses ultraviolet light sources for plate exposure, which is particularly useful in flexographic printing applications and high-speed production environments.

CTP (Computer-To-Plate) technology is a process that directly transfers digital files to printing plates. It requires the complete digitization of all print materials and layouts to ensure a precise plate-making process.

In the CTP process, if a printing plate is damaged, layout errors occur, or adjustments are needed after plate exposure, it is not possible to simply repair the existing plate. Instead, a completely new plate must be made. This is because once a CTP plate is created, partial modifications are not possible, and a new plate must be made by updating the digital files and reassembling the layout.

This fully digital process reduces the complexities of traditional plate-making, improving speed and accuracy. However, it also means that once an issue arises with the plate, the cost of re-making the plate may be high. Therefore, ensuring the accuracy of the initial digital files and layout quality is crucial for the CTP process.

In the traditional CTF process, film-based plate-making requires chemical development and fixing, which generates waste and wastewater, causing environmental pollution. However, the CTP process omits these chemical treatments, avoiding the production of harmful waste and reducing environmental pollution. Additionally, the CTP process no longer uses film, eliminating the common chemical odors found in traditional plate-making, thus improving the air quality of the working environment.

A CTP (Computer-to-Plate) machine is an advanced printing device that directly transfers digital images to printing plates, eliminating the steps of shooting and chemical treatment involved in traditional plate-making.

With digital plate-making technology, the CTP machine significantly improves print quality and production efficiency, reduces errors and waste, and is commonly used in commercial printing, packaging printing, label printing, and security feature printing.

| Application Area | Description |

| Commercial Printing | CTP machines are widely used in high-quality commercial printing such as newspapers, brochures, magazines, and catalogs. They can accurately reproduce complex designs and ensure high-quality printing results. Compared to traditional plate-making methods, CTP improves production speed, reduces human errors, and enhances overall print quality by directly converting digital files into printing plates. |

| Packaging Printing | In the packaging printing industry, CTP machines are used to accurately replicate packaging designs, especially for logos, product images, and text accuracy. CTP ensures fine reproduction of graphics, colors, and text, making it the preferred technology for high-quality packaging printing, particularly in multi-color printing and high-precision applications. |

| Label Printing | Label printing requires very fine and vivid graphics and text. CTP machines can accurately reproduce intricate patterns and clear text, ensuring the quality of each label, especially for industries like food, pharmaceuticals, and cosmetics, where there are high requirements for labels. The high precision of CTP makes graphics on labels more detailed and text clearer. |

| Advanced Security Features | CTP machines also play a crucial role in printing products with advanced security features, such as banknotes, passports, and other printed items with complex anti-counterfeit functions. These products often contain watermarks, microtext, and special patterns. CTP's precision ensures that every detail is perfectly reproduced, improving security and reducing the risk of counterfeiting. |

There are various offset CTP systems on the market, each with unique features and capabilities to cater to different applications.

| Feature | Thermal CTP Systems | Violet CTP Systems | Ultraviolet (UV) CTP Systems |

| Exposure Method | Uses a thermal laser to expose photosensitive plates. | Uses a violet laser to expose violet-light-sensitive plates. | Uses UV lamps or lasers to expose photosensitive plates. |

| Plate Sensitivity | Sensitive to heat (thermal exposure). | Sensitive to violet light (needs safelight handling). | Sensitive to ultraviolet light (requires UV exposure). |

| Image Creation | Image formed by heat hardening photosensitive coating. | Image created by violet light exposure, with a chemical reaction. | Image formed by UV light exposure, with a chemical reaction. |

| Speed | Moderate speed, slower than violet systems. | Faster than thermal systems. | Fast, suitable for high-speed environments. |

| Image Quality | High-quality, precise image transfer. | Lower resolution compared to thermal, but still good quality. | High-quality, sharp image transfer. |

| Plate Handling | Less sensitive to light, easier to handle. | Plates need careful handling to avoid exposure to ambient light (yellow safelight). | Plates need careful handling due to UV sensitivity. |

| Environmental Impact | Reduced chemical waste, more eco-friendly than analog methods. | More eco-friendly than traditional methods. | Generally eco-friendly, but UV lamps may require maintenance. |

| Cost | Higher equipment and consumable cost. | Lower equipment and consumable cost. | Higher cost for equipment and UV plates. |

| Applications | High-resolution printing, such as magazines, brochures, and packaging. | Cost-effective for commercial printing with moderate quality. | High-quality, high-speed printing for packaging and fine art. |

| Maintenance | Requires periodic maintenance of thermal laser equipment. | Requires careful plate handling and safelight storage. | Requires maintenance of UV lamps or lasers. |

This table outlines the differences in exposure method, image quality, speed, cost, and applications among the three main types of CTP systems, allowing for a quick comparison of their features.

When selecting a CTP machine, consider:

CTP technology has become the industry standard for offset printing, combining speed, accuracy, and environmental benefits. By understanding the system, plate, and operational requirements, businesses can optimize their workflow for high-quality output and cost efficiency.

Users viewing this material also viewed the following

Further reading: computer to plate machinecomputer to platecomputer to plate ctpcomputer to plate printingcomputer to plate systemsctp computerctp computer to platectp computer to plate machine